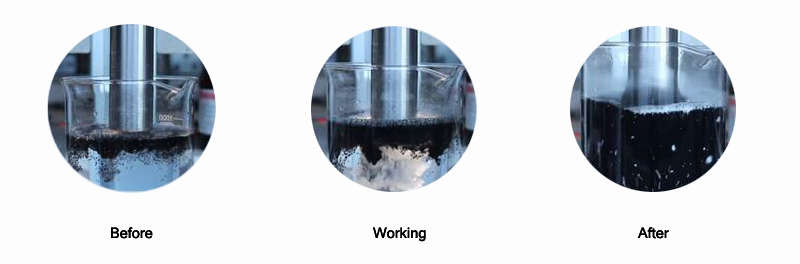

Ultrasonic dispersion refers to the process of dispersing and de-agglomerating particles in the liquid through the "cavitation" effect caused by the vibration of the ultrasonic tool head in the liquid with the liquid as the medium (dispersing agent is not required). It can be used in the manufacturing of catalysts, matting agents, pigments, graphite, paint coatings, alumina, compound fertilizers, and nanomaterials

Ultrasonic dispersion refers to the process of dispersing and de-agglomerating particles in the liquid through the "cavitation" effect caused by the vibration of the ultrasonic tool head in the liquid with the liquid as the medium (dispersing agent is not required). Ultrasonic dispersion can obtain micron or even nano-level particles (0.1-10μm). When the ultrasonic vibration is transmitted to the liquid, due to the high sound intensity, a strong cavitation effect will be excited in the liquid, thereby generating a large number of cavitation bubbles in the liquid. As these cavitation bubbles are generated and blasted, micro-jets will be generated to break up solid particles that are heavy in the liquid. At the same time, due to the vibration and dispersion of ultrasonic waves, the solid and liquid are more fully mixed, which promotes most chemical reactions. It can be used in the manufacturing of catalysts, matting agents, pigments, graphite, paint coatings, alumina, compound fertilizers, fillers, herbicides, fungicides, powder emulsions, and nano materials. It is widely used in teaching, scientific research, and production in the fields of food, cosmetics, medicine, chemistry, new materials, agronomy, chemical industry, sewage treatment, nanomaterials, etc.

Features

1. The ultrasonic system has multiple protections and is easy to operate

2. Using closed-loop ultrasonic system, stable power output, strong anti-interference ability

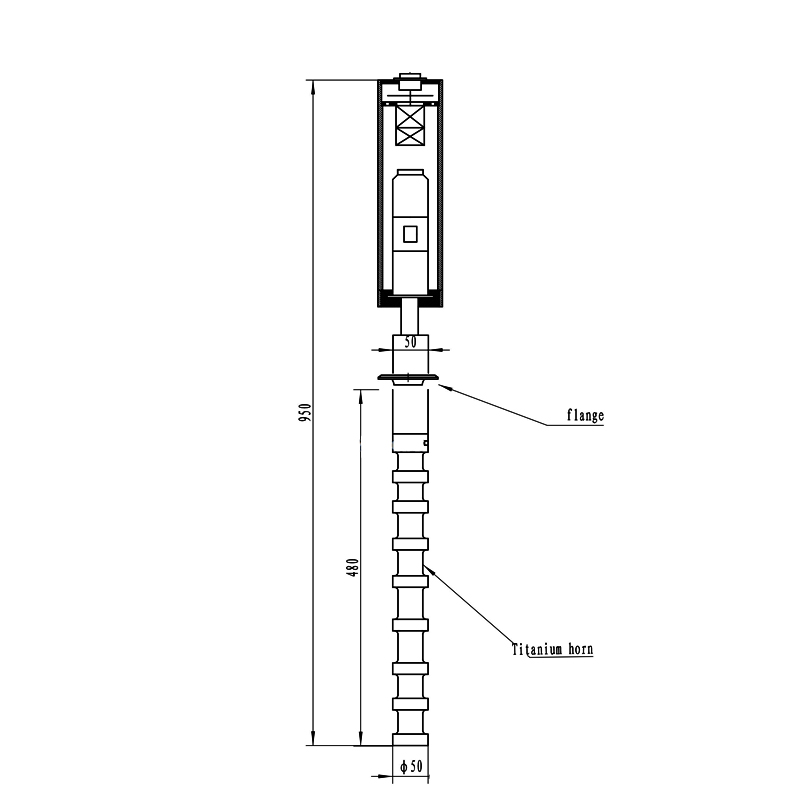

3. High dispersion quality, narrow droplet size distribution range, which can be 0.1~10um or narrower

4. The dispersion cost is low, and a stable solvent can be produced without or only a small amount of dispersant

5. Fast response and high efficiency

6. The upgrade of ultrasonic mixing equipment can be completed without changing the customer's existing production equipment and process flow

7. According to customer requirements, tailor-made solutions can be used in combination with multiple sets to increase the radiation area and increase the output

Industry Application:

Biological industry: petroleum, natural plants, polysaccharides, flavonoids, alkaloids, polyphenols, organic acid oils extraction

Laboratory applications: cell disruption, material dispersion (suspension making) and coagulation.

Chemical industry: textile process and dyeing process, batik process, defoaming.

Water treatment: Pollution of water quality, vibrating algae and marine organisms in the manufacturing industry.

Graphene: Graphene particles, graphene nanoparticles produce.

Food and cosmetics industry: wine aging, cosmetics particles refined