Ultrasonic homogenization means that under the effect of "cavitation", ultrasonic high shear force breaks the clumps and cell tissues in the liquid to produce fine and uniform particles

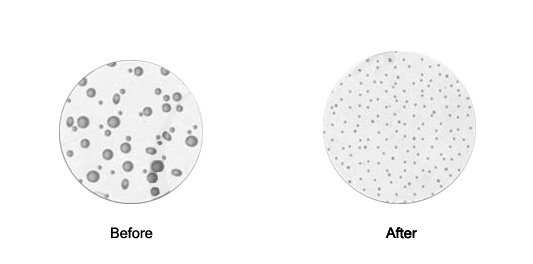

Ultrasonic homogenization means that under the effect of "cavitation", ultrasonic high shear force breaks the clumps and cell tissues in the liquid to produce fine and uniform particles. The ultrasonic homogenizer can break the powder agglomerates in the liquid, while the traditional agitator and high-shear mixer cannot. High cavitation shear disperses and homogenizes the agglomerated particles, resulting in a higher specific surface area. PUTSONIC can process homogeneous liquids in batches for industrial production. We can customize ultrasonic systems and tool heads with different amplitudes according to customers.

Features

1. The ultrasonic system has multiple protections and is easy to operate

2. Using closed-loop ultrasonic system, stable power output, strong anti-interference ability

3. The homogenization quality is high, and the droplet size distribution range is narrow, which can be 0.1~10um or narrower

4. Reduce friction and wear and cleaning time

5. Fast response and high efficiency

6. The upgrade of ultrasonic mixing equipment can be completed without changing the customer's existing production equipment and process flow

6. According to customer requirements, tailor-made solutions can be used in combination with multiple sets to increase the radiation area and increase the output

Industry Application:

Biological industry: petroleum, natural plants, polysaccharides, flavonoids, alkaloids, polyphenols, organic acid oils extraction

Laboratory applications: cell disruption, material dispersion (suspension making) and coagulation.

Chemical industry: textile process and dyeing process, batik process, defoaming.

Water treatment: Pollution of water quality, vibrating algae and marine organisms in the manufacturing industry.

Graphene: Graphene particles, graphene nanoparticles produce.

Food and cosmetics industry: wine aging, cosmetics particles refined