Please share the stud size of ultrasonic horn you need !

20KHz/15KHz ultrasonic steel horn

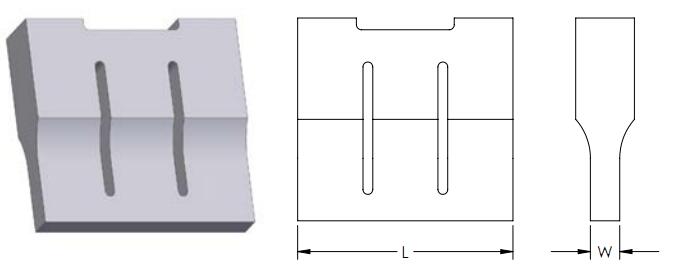

L110xW15xH125 L160xW25xH170

L110xW20xH125 L200xW25xH170

L200xW20xH125 L110xW25xH170

L250xW20xH125 L120xW25xH170

L160xW45xH125 L270xW25xH170

L160xW25xH125 L300xW25xH170

20KHz 15KHz Ultrasonic Steel Horn for KN95 Face Mask

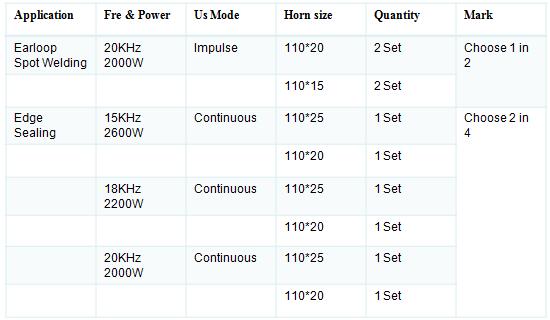

We offer the 20KHz 15KHz 18KHz ultrasonic steel horn for KF94 ,KN95 ,Medical face mask making .If your current face mask machine stop running because of the ultrasonic horn etc parts broken ,welcome to contact with us .

We can offer the different size and frequency ultrasonic horn for it . The different size and ultrasonic power parts list as below :

KN95 Face mask ultrasonic welding horn system size

KF94 Face mask ultrasonic welding horn system size

Disposable face mask ultrasonic welding horn system size

(Note:Above list size just one part ,also we can according to your application to design the size )

Ultrasonic horn also named as ultrasonic sonotrode, ultrasonic welding head,ultrasonic waveguide,ultrasonic probe.It’s transmit the ultrasonic vibration energy to plastic part and with pressure to reach welding result .Usually it’s made of high grade material like Aluminum ,Titanium and tool steel .

PUTSONIC design and manufacture high quality ultrasonic horn and fixtures for all brand ultrasonic welding machine likeHerrmann,BRANSON,Rinco,Dukane,Telsonic,Mecasonic,KKS etc .all ultrasonic horns are design with FEA simulation program which can let our engineer knows the vibratory action of horn before manufacturing .Usually we use the Solidworks,Pro-E,UG,AUTOCAD etc software . We suggest the customer send us the stp format for the application files .

Service we offer:

Application:

•It is suitable for welding the thermal plastic such like: HDPE、PP、PE、ABS、PVC、PC、EVA、PMMA、PS、PP、PBT、PETG, and other plastic, also for fiber cotton, chemical fiber, metal hardware in the aspects of riveting, cutting, sealing, welding, spot welding,embossing,fixed position for files, melt welding

•According to customer needs to replace riveting, welding, embedded, removing process, relative to other traditional process (such as adhesives, hot welding or screw connection), has high production efficiency, good weld quality, environmental protection and energy saving advantages

Various Plating to protect the horns

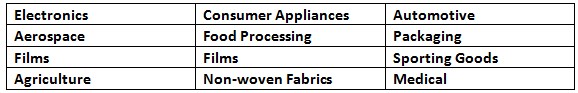

Industries we served