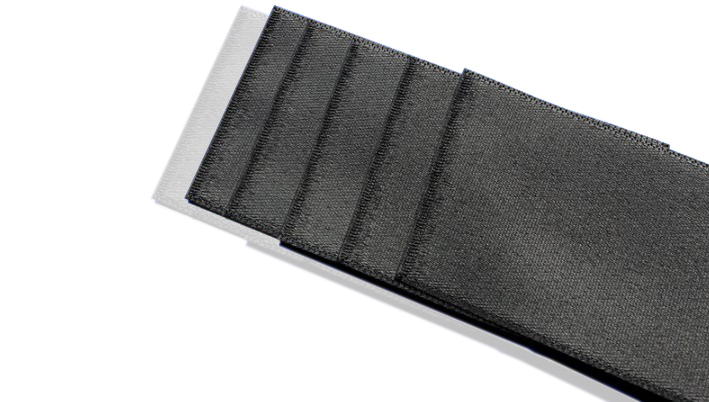

Combination of the ultrasonic welding technology and traditional cutting, when the ultrasonic generator is working, the ultrasonic energy is transmitted to the welding horn(sonotrode) through the ultrasonic transducer and violently vibrating and rubbing with the die mould, so as to achieve the effect of cutting and make the cut product. It has the advantages of more beautiful, firmer, more efficient and faster production efficiency (complete and beautiful incision, neat and smooth cutting edges, no burrs, no loose edges). Generally, it is only necessary to replace the ultrasonic horn(sonotrode) and knife die mold to obtain gift belts, strip nylon belts, strip ribbons .

What about ultrasonic horn/sonotrode of materials that we generally use? Usually we use two materials, one is titanium alloy with hardened coating, which is generally more expensive; the other is our commonly used steel material, which achieves wear resistance through hardening treatment, and the price is generally acceptable.

In the range. Materials suitable for ultrasonic cutting: chemical synthetic fiber fabrics, or blended fabrics containing chemical fibers, and chemical films containing more than 30% chemical fabrics can be processed into desired products, such as Nylon fabric, knitted fabric, non-woven fabric, T/ R cloth, polyester cloth, glitter cloth, multi-layer cloth, and all kinds of laminated film paper can be applied.

To know more, welcome to contact us: