With the changes and development of the times, the hook and loop is not only just used to the fields of clothing, shoes and hats etc. In recent years, the application of hook and loop has also been favored by the electronic high-tech industry and is closely related to high technology products. Hook and loop Products have been developed and designed, and mass production has been put into use of our life . A large number of high-tech electronic products such as Dell, Samsung, Apple, and Lenovo have used Velcro hook and loop straps. hook and loop products with different designs can be seen everywhere in our electronic life. . With the development of hook and loop in the high-tech field, traditional Velcro production technology has been unable to meet people's needs for its beauty and long-term performance.

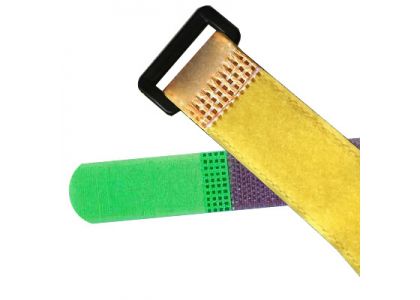

The width of the hook&loop strap is between 10mm~150mm, and the commonly used specifications in the market are: 12.5mm, 16mm, 20mm, 25mm, 30mm, 40mm, 50mm, 60mmm, 75mm, 80mm, 100mm, 110mm, 115mm, 125mm, 135mm.

There are two main traditional velcro hook and loop making methods . One is needlework. There is no bond between the cloth and the cloth sewn with needlework, but a thin thread is used to tie them together. After long-term use, the connecting line is easy to break. Causes the velcro tape to fail, and the stitched interface is clearly visible and the aesthetics is not good: the second is the adhesive connection, this method has a higher aesthetics than needlework, but there is also a phenomenon of degumming after long-term use, which causes the hook&loop tape to fail .

Ultrasonic welding is also the latest and most widely used application. This bonding method does not require needles and threads, does not require any auxiliary materials, and can weld all kinds of fabrics, such as hook and loop, elastic bands etc together. Ultrasonic welding is to focus the mechanical vibration energy of the ultrasonic on the ultrasonic welding head/ultrasonic horn, and the ultrasonic energy is transmitted to the welding area through the ultrasonic welding head. Because the welding area, that is, the acoustic resistance at the interface of two weldings, will generate local high temperature, causing two The contact surface of the cloth melts quickly, and after a certain pressure is applied, it becomes one body. When the ultrasonic stops, let the pressure continue for a few seconds to make it solidify and shape, so that a solid molecular chain is formed to achieve the purpose of welding , and the welding strength can be close to the strength of the un-weld material.