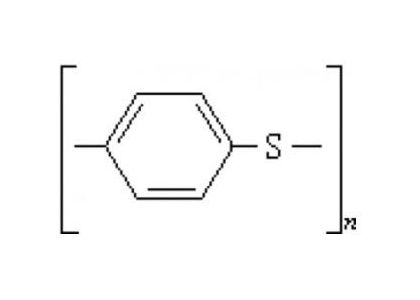

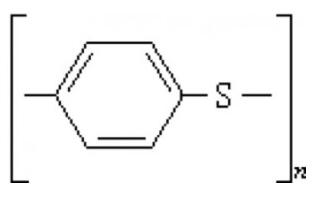

Polyphenylene sulfide, or shortname PPS . The molecular structure of PPS is relatively simple. The molecular backbone is alternately arranged by benzene rings and sulfur atoms. A large number of benzene rings give PPS rigidity, and a large number of sulfide bonds provide flexibility. It has the advantages of hard and brittle, high crystallinity, flame retardant, good thermal stability, high mechanical strength, and excellent electrical properties.

PPS is a crystalline (55%-65% crystallinity) high-rigidity white powder polymer with high heat resistance (continuous use temperature up to 240 degrees), mechanical strength, rigidity, flame retardancy, chemical resistance, electrical properties , Resin with excellent dimensional stability, excellent wear resistance, creep resistance, excellent flame retardancy (up to UL94V-0), and maintain good electrical properties under high temperature and high humidity. Good fluidity, easy to shape, almost no shrinkage pits during molding. It has good affinity with various inorganic fillers. If the physical and mechanical properties and heat resistance are improved, the reinforcing materials include glass fiber, carbon fiber, aramid fiber, metal fiber, etc., mainly glass fiber. Inorganic fillers include talc, kaolin, calcium carbonate, silica, molybdenum disulfide and so on.

PPS/PTFE, PPS/PA, PPS/PPO, and other alloys have been commercialized. PPS/PTFE alloy improves the brittleness, lubricity and corrosion resistance of PPS, and PPS/PA alloy is a high toughness alloy.

Glass fiber reinforced PPS has excellent thermal stability, wear resistance, creep resistance, excellent mechanical and electrical properties in a wide range (temperature, humidity, frequency), small dielectric quantity, and dielectric loss Low.

Industry Application:

When nylon (PA), polyoxymethylene (POM), polyethylene terephthalate (PET) and polyaluminum (PSU) are used in various fields of the machinery industry, they have disadvantages and cannot meet the technical requirements, and the use of polyimide (PI) ) Polyetheretherketone (PEEK) and polyamideimide (PAI) are too expensive. PPS should be an ideal engineering plastic.

1. Machinery industry: In the machinery industry, it is especially used in the preparation of parts under high humidity and strong corrosive environments. Used for shells, structural parts, wear-resistant parts and sealing materials, such as: pump housings, pump wheels, valves, bearings, bearing brackets, piston rings and gears, pulleys, fans, meteorometer parts, flanges, universals Head, counter, level, etc.

2. Electronic and electrical appliances: PPS can account for 30% in the electronic and electrical industry. It is suitable for high-temperature electrical components with an ambient temperature of more than 200°C; it can be used to manufacture electric generators and engines, electric heating brackets, starter coils , Shielding covers and blades, etc.; on televisions, it can be used for high-voltage housings and sockets, terminals and terminal boards, etc.; in the electronics industry, manufacturing transformer choke coils and relay skeletons and shells, integrated circuit carriers; using high frequency Performance, manufacturing H-class bobbin and trimmer capacitors, etc. Miniature electronic component packaging, connectors, wiring connectors, sockets, coil frames, motor shell electromagnetic adjustment plates, TV tuner shafts, relays, trimmer capacitors, fuse holders, radio tape recorders, magnetic therapy devices and other parts. It is also used in precision instruments: computers, timers, tachometers, photocopier cameras, temperature sensors, and housings and parts of various measuring instruments.

3. Automotive industry: PPS is used in the automotive industry for about 45%, mainly used in automotive functional parts; igniters, heaters, carburetors, clutches, transmissions, gear boxes, bearing brackets, lampshades, bumpers, fans, exhaust systems As well as parts for reflectors and lamp holders. It can replace metal to make exhaust cylinder circulation valve, water pump impeller, pneumatic signal regulator, etc.

4. Household appliances: protective coatings and parts for hot air cylinders, hair curlers, hair dryers, hair irons, microwave ovens, coffee cookers, clothes dryers, electric irons, rice cookers, etc.

5. Chemical industry: PPS has excellent adhesion and corrosion resistance, and is extremely suitable for lining chemical equipment.