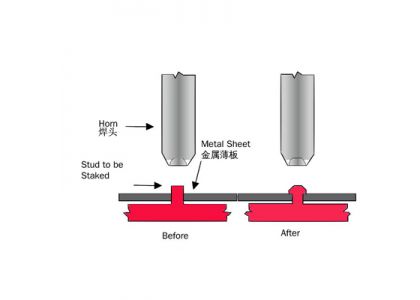

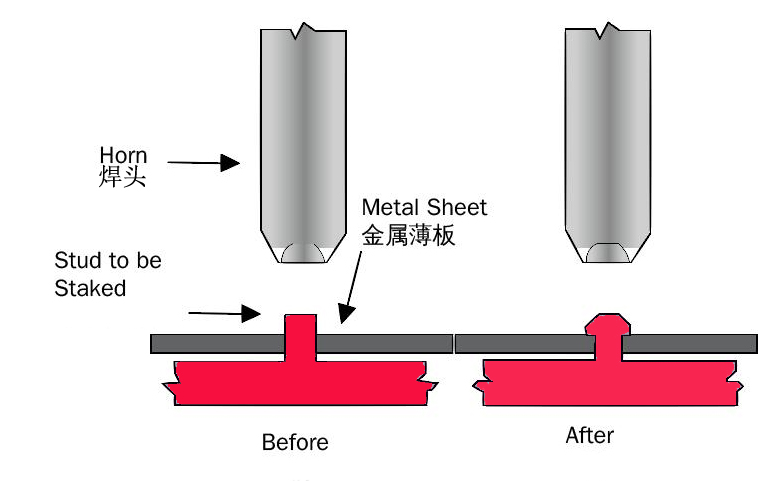

Ultrasonic plastic staking or riveting is that the plastic column or the plastic stud passes through the hole of another part and higher than the plane of the other part. During the stake welding process, the high-frequency vibrating ultrasonic horn touches the top of the plastic column or stud firstly , and starts to melt from top to bottom. The molten plastic fills another part to form a mushroom head, which effectively fixes the opponent parts to achieve the purpose of connecting and fixing two parts together.

The advantages of ultrasonic riveting are that the welding cycle time is short (in many cases less than 1 second), there will be no rebound after fixing, and it's high efficiency, multiple plastic column or plastid stud can be riveted at a time, the design of plastic parts is simple, no screws and other consumables are required, which saves a lot of labor and material costs.

If you want to have lower economic costs and strong versatility, you can use a handheld ultrasonic welding machine . For some large parts (such as car dashboards and door trims), you can also use automation multiple welding units with one-time welding to save labor costs. .

Whether the product meets the required tensile force, we need to consider the diameter and height of the cylinder when designing the product, as well as the height and diameter after riveting, which is what we call the design of the welding tip. Want to know if your design is reasonable, please contact us!