PUTSONIC Ultrasonic weld impact treatment equipment is widely used in ships, petrochemicals, aviation, railways, wind turbines, steel or composite bridges, heavy lifting machinery and other fields. It is suitable for post-weld residual stress relief treatment of various material welded structures to achieve the purpose of extending the fatigue life of welded steel structure and improving its fatigue strength, And it can eliminate the stress and residual stress in the welding process, it's especially suitable for post-weld stress treatment of ordinary joints, load-bearing joints, and dissimilar material welded joints.

I. What is welding impact?

Welding impact is the stress generated by welding of a welded component. The internal stress generated in the weldment during the welding process and the change in the shape and size of the weldment caused by the welding thermal process. The root causes of welding stress generation and deformation are the non-uniform temperature field of the welding process and the local plastic deformation and the structure with different specific volume. It will affect the function and appearance of weldments under certain conditions, so they must be considered in welding structural products, engineering design and manufacturing, and construction.

II. The reasons of welding impact formed

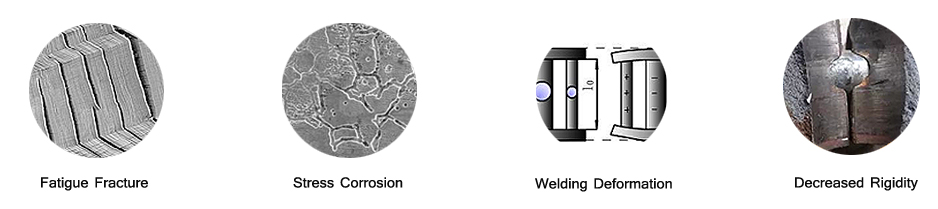

1. For all fusion welding, there is a large residual stress in the weld and its heat-affected zone. The existence of residual stress will cause the deformation and cracking of the welded component and reduce its bearing capacity, so the existence of welding residual stress makes the welding The service life of structural parts is greatly shortened;

2. At the same time,stress concentration on the welding place of pits,reinforcement,undercut ;

3. The slag defects and micro-cracks from the weld toe form the premature initiation source of cracks. Due to the influence of residual tensile stress, stress concentration and crack initiation sources, the fatigue life of welded joints is greatly reduced.

4. Residual stresses are concentrated near the welding seam. When the welding residual stress and the load working stress are superimposed, and its value exceeds the yield pole of the material, the workpiece will produce welding deformation and fracture near the welding seam.

5. When analyzing the influence of residual stress, even if the residual stress value of the welded component is far below the yield limit of its material, if there is a serious stress concentration, the welded structure will be affected by the residual stress during its transportation and use. Destructive plastic deformation occurs due to the release of stress.

Technical parameter:

|

Model |

PUT-C20G |

|

Frequency |

20KHz |

|

Maximum Output |

500 Watt |

|

Temperature Range |

0 ~ 300 °C |

|

Power Supply |

220V / 50-60 Hz |

|

Amplitude |

30%-100% adjustable |

|

Cable length |

Standard 3 Meters |

|

Impact gun |

Weight:4.5KG Length: a.500mm |