Ultrasonic tin soldering is to apply ultrasonic vibration to the liquid tin material to produce a cavitation effect. This effect is used to destroy and remove the oxide film on the surface of the base material, so that the liquid tin material wets the surface of the base material. The ultrasonic soldering head is applied at a position away from the tin seam. First, use the heating coil to heat the tin and the base material to the soldering temperature, and then transmit the ultrasonic vibration higher than 20 kHz to the base material through the ultrasonic soldering head, the amplitude range is 0-100μmm, the vibration time is between 0.5-10s. After the ultrasonic vibration end, the base material is allowed to cool naturally, and the distinguishing feature of ultrasonic TIN soldering is the low-temperature solder-free connection. With the rapid development of advanced welding technology and new soldering materials, as a green and environmentally friendly ultrasonic soldering technology, it has been favored by academia and industry at home and abroad.

Technical parameter:

|

Model |

PUT-6010TS |

|

Frequency |

60KHz |

|

Maximum Output |

100 Watt |

|

Temperature Range |

150 ~ 500 °C |

|

Power Supply |

220V / 50-60 Hz |

|

Amplitude |

30%-100% adjustable |

|

Cable length |

Standard 2 Meters |

|

Soldering head material |

Steel |

Application

- Welding the titanium rod to the sapphire substrate;

- Solar cell contact: silicon si single wafer, thin film solar cell, dye-sensitized solar cell;

-The niobium coil is wound on the glass-ceramic rod;

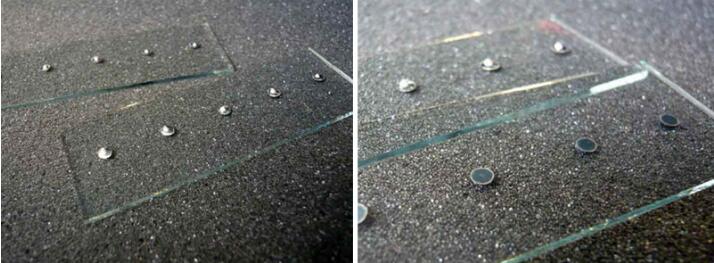

-Tin plating of optical glass;

- Welding 120μm glass optical fiber into 0.5mm bronze hole;

-The copper wire is in electrical contact with the aluminum sheet of the glass substrate;

-Contact with ceramic-carbon hybrid superconductor, welding point diameter 0.8mm