Ultrasonic dispersion refers to the process of dispersing and de-agglomerating particles in the liquid through the "cavitation" effect of ultrasonic waves in the liquid using liquid as a medium.

Ultrasonic technology, as a physical means and tool, can produce various conditions in liquids. This phenomenon is called sonochemical action, and related ultrasonic equipment is called ultrasonic sonochemical equipment (abbreviated as "sonochemical equipment"). Ultrasonic dispersion equipment is an application of sonochemical equipment, which can be used for water treatment, solid-liquid dispersion, de-agglomeration of particles in liquid, and promotion of solid-liquid reaction.

Due to the thermal motion of particles (atoms, molecules or molecular groups), the phenomenon of matter migration spontaneously produced is called "diffusion".

Diffusion can be carried out between solid, liquid, and gas phases of the same substance, or between different solids, liquids and gases, mainly due to differences in concentration or temperature. Generally, it diffuses from the area with higher concentration to the area with lower concentration, until the concentration of each part in the phase reaches uniformity or the concentration between the two phases reaches equilibrium. When substances are in direct contact with each other, it is called free diffusion. If the diffusion is through the isolation material, it is called penetration.

The phenomenon of diffusion plays a big role in nature. It keeps the atmosphere around the entire earth's surface with the same composition. The diffusion of various salt solutions contained in the soil facilitates the absorption of plants and facilitates growth. In addition, diffusion is used in many industries such as semiconductors and metallurgy. Diffusion, heat conduction and viscosity are commonly known as transport phenomena. They respectively move matter (mass), heat energy, and momentum from one position to another. And to achieve uniformity of concentration or temperature.

Ultrasonic dispersion can be divided into emulsion dispersion (liquid-liquid dispersion) and suspension dispersion (solid-liquid dispersion), and has been applied in many fields. The applications of ultrasonic for the dispersion of suspensions include: the dispersion of titanium oxide in water or solvents in the coating industry, the dispersion of dyes in molten paraffin, the dispersion of particles in the pharmaceutical industry, and the dispersion of powder emulsions in the food industry. Dispersion and so on.

working principle

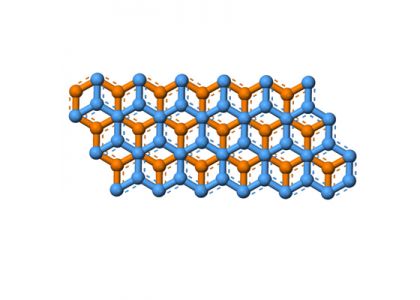

The 20k3000W ultrasonic graphene peeling and dispersing machine is composed of ultrasonic vibration parts and ultrasonic driving power supply.

Ultrasonic vibration components mainly include high-power ultrasonic transducers, horns, and tool heads (transmitting heads), which are used to generate ultrasonic vibrations and emit this vibration energy into the liquid.

The ultrasonic drive power supply is a device specially used to drive the ultrasonic vibrating component to work, and control the various working states of the ultrasonic vibrating component. It converts general mains electricity into a high-frequency alternating current signal, and drives the transducer to produce ultrasonic vibration.

When the ultrasonic vibration is transmitted to the liquid, due to the high sound intensity, a strong cavitation effect will be excited in the liquid, thereby generating a large number of cavitation bubbles in the liquid. As these cavitation bubbles are generated and ruptured, micro-jets will be generated to break up solid particles that are heavy in the liquid. At the same time, due to the ultrasonic vibration, the solid and liquid are more fully mixed, which promotes most of the chemical reactions. In the medical field, if phospholipids and cholesterol are mixed, after ultrasonic dispersion, smaller particles (about 0.1μm) can be obtained for intravenous injection.

Application

Ultrasonic dispersion has a wide range of applications in many fields: such as food, cosmetics, medicine, chemistry, etc.

The application of ultrasound in food dispersion can be roughly divided into three situations: liquid-liquid dispersion (emulsion), solid-liquid dispersion (suspension), and gas-liquid dispersion.

Solid-liquid dispersion (suspension): such as powder emulsion dispersion.

Gas-liquid dispersion: For example, the production of carbonated beverage water can be improved by the CO2 absorption method to improve stability.

Liquid-liquid dispersion (emulsion): e.g. emulsification of ghee to make high-grade lactose; dispersion of raw materials when making sauces, etc.

20k3000W ultrasonic graphene peeling and dispersing machine

Ultrasonic dispersion can also be used for the preparation of nanomaterials; for the detection and analysis of food samples, such as the use of ultrasonic dispersion liquid-phase micro-extraction technology to extract and enrich trace amounts of double hope in milk samples.

The banana peel powder is pre-treated by the physical modification method of ultrasonic dispersion combined with high pressure cooking, and then the banana peel powder is enzymatically hydrolyzed with amylase and protease.

Compared with the insoluble dietary fiber (IDF) obtained by pure enzyme treatment without pretreatment, the hydrodynamic, binding hydropower, holding power and swelling properties of the 1DF obtained after pretreatment are significantly improved.

The preparation of tea dopan liposomes by the thin-film ultrasonic dispersion method can improve the bioavailability of tea dopan, and the prepared tea dopan liposomes have good stability.

Using ultrasonic dispersion of immobilized lipase, as the ultrasonic dispersion time continues to increase, the immobilization rate continues to increase, and increases slowly after 45 minutes; with the extension of ultrasonic dispersion time, the activity of the immobilized enzyme gradually increases, reaching at 45 minutes Value, then began to decrease, showing that the enzyme activity will be affected by the ultrasonic dispersion time.

Homogenization and dispersion of various coatings, dyes, nanomaterials, etc.; various industrial additives and food fields and mixing. Can be applied to various solid-liquid dispersion and liquid-liquid dispersion fields